Centrifugation, a fundamental process in biological and chemical research, relies on the precise performance of centrifuge tubes to achieve optimal results. These tubes play a critical role in separating components based on density and are essential for a wide range of applications, including sample preparation, cell isolation, and biomolecule purification. High-quality centrifuge tubes are designed to withstand the extreme forces exerted during centrifugation, ensuring sample integrity, reproducibility, and safety. In this exploration, we delve into the science of centrifugation and the pivotal role of high-quality centrifuge tubes in maximizing results across diverse research disciplines.

Centrifugation is a process that utilizes centrifugal force to separate components within a liquid medium based on their density. This fundamental technique is employed in various scientific and clinical settings to isolate and purify substances, ranging from cells and subcellular organelles to proteins and nucleic acids. The success of centrifugation hinges not only on the performance of the centrifuge itself but also on the quality and reliability of the centrifuge tubes used to contain the samples.

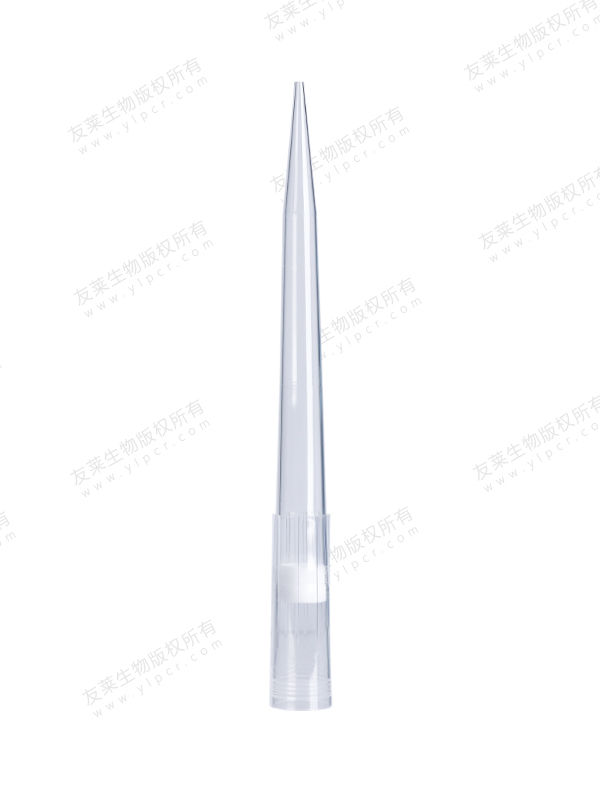

High-quality centrifuge tubes are engineered to withstand the extreme forces exerted during centrifugation, ensuring sample integrity and preventing leakage or breakage. These tubes are constructed from materials such as polypropylene or ultraclear polymers that exhibit exceptional strength, chemical resistance, and transparency. The robust construction of these tubes allows them to endure high-speed centrifugation without compromising the integrity of the samples, thereby ensuring reproducible and reliable results.

Moreover, high-quality centrifuge tubes are designed with precise sealing mechanisms, such as screw caps or secure snap closures, to prevent sample leakage and maintain a hermetic seal during centrifugation. This feature is crucial for safeguarding the integrity of the samples, particularly when working with valuable or sensitive materials. The ability of these tubes to withstand the forces exerted during centrifugation without compromising the containment of the samples is essential for ensuring the accuracy and reproducibility of experimental outcomes.

In addition to their mechanical robustness, high-quality centrifuge tubes are engineered to provide optimal clarity and transparency. This transparency is essential for visualizing the contents of the tubes, monitoring sample integrity, and facilitating accurate sample handling. Clear and transparent tubes enable researchers to observe phase separations, monitor the formation of gradients, and visually inspect the quality of the separated components post-centrifugation. This visual feedback is invaluable for assessing the success of the centrifugation process and ensuring the purity and integrity of the isolated samples.

Furthermore, high-quality centrifuge tubes are available in a variety of configurations to accommodate diverse centrifugation protocols and sample volumes. These configurations include conical bottom tubes for pelleting applications, flat-bottom tubes for high-speed centrifugation, and specialized tubes for gradient centrifugation. The availability of these versatile tube designs allows researchers to tailor their centrifugation protocols to specific applications, ensuring optimal performance and maximal sample recovery.

The pivotal role of high-quality centrifuge tubes in maximizing results extends beyond their mechanical attributes to encompass their impact on sample safety and researcher well-being. These tubes are designed to meet stringent quality and safety standards, ensuring that they are free from contaminants, leachables, and other potential sources of sample contamination. Additionally, high-quality centrifuge tubes are often certified as RNase, DNase, and endotoxin-free, making them suitable for molecular biology and clinical applications where sample purity is paramount.

English

English русский

русский 中文简体

中文简体